Resin Flow Analysis - SOLIDWORKS Plastics

For designers involved in the production of injection molds, using CAE resin flow analysis, Analyzing the causes of defects in each molding process, relying on the experience and intuition of skilled technicians, It is possible to qualitatively and quantitatively verify effective measures before mold processing.

In particular, SOLIDWORKS Plastics, a resin flow analysis software integrated with SOLIDWORKS, Because it is fully integrated with SOLIDWORKS (CAD), Predict the occurrence of molding defects (eg, short shots, sink marks, air traps, etc. due to uneven wall thickness) due to the shape of the product in advance, In addition to optimizing the molding conditions that affect the cycle time, It is possible to verify the effectiveness of the measures.

In addition, by performing packing pressure analysis and cooling pipe layout analysis, prediction of gate sealing time (packing time) In addition to being able to study effective cooling pipe arrangements, In the case of set picking or multiple picking, by using the runner balance optimization function, It is possible to automatically change the runner diameter and gate diameter based on the volume of the molded product, and optimize the shape of the runner.

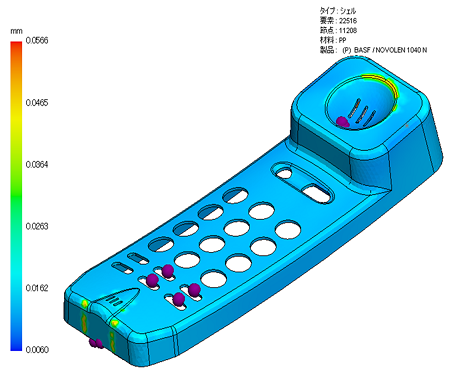

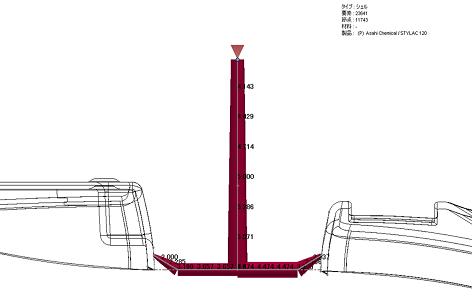

1) Prediction results of air trap and sink mark occurrence position

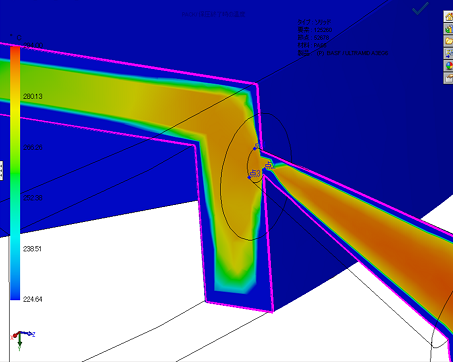

2) Packing analysis / Gate seal condition analysis

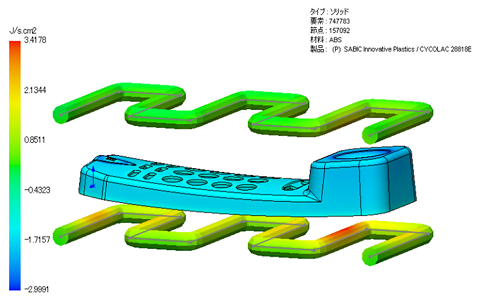

3) Cooling pipe arrangement and cooling analysis results

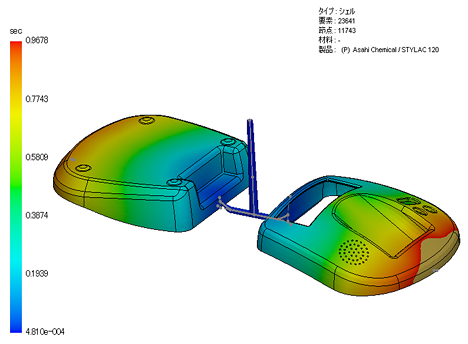

4) Runner balance optimization analysis

5) Runner diameter after optimization calculation

Techspire Co., LTD.

Techspire Co., LTD.